VMR-MC600(G)

SYSTEM CONTROLLER

The VMR-MC600(G) is a universal core controller for mobile robots, independently developed by Lanxin Robotics. This controller integrates a core processor, IO control, bus communication and power management into a single unit. Designed to industrial standards, it features a compact size, powerful computing capability, high integration, and a wide range of functions. As of 2023, over 12,000 units have been deployed.

TECH SPECS

Basics

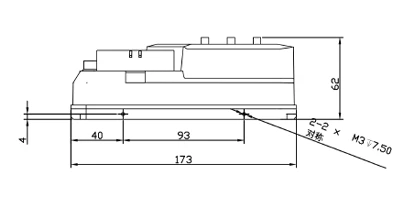

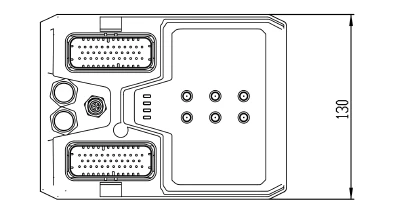

| Dimensions(L*W*H) | 173 mm * 130 mm * 62 mm |

| Net Weight | 800 g |

| Operating Voltage | 48 VDC |

| Self-consumption | 7 W |

| Operating Temperature | -10~50 °C |

| Storage Temperature | -20~60°C |

| Operating Humidity | 10~90% RH, non-condensing |

| Protection Level | IP54 |

Digital Interfaces

| DI Interfaces(12 channels) | 1 channel for hand charging status monitoring, 2 channels for fork upper/lower limit positions, 2 channels for fork left/right positioning, 1 channel for chassis operation permission, 6 reserved channels |

| DO Interfaces(4 channels) | 1 channel for charging handshake, 1 channel for auxiliary device power supply, 1 channel for chassis motor power supply, 1 channel for auxiliary device operation permission |

Power Supply Interface

| 24VDC Interface | 1 channel, maximum power 200W |

Bus Interfaces

| CAN Interfaces | 3 channels (2 for MCU, 1 for core board) |

| RS485 Interfaces | 5 channels (4 for MCU, 1 for core board) |

| RS232 Interfaces | 2 channels (1 for MCU, 1 for core board) |

Network Interfaces

| Ethernet | 2 channels, 10/100/1000Mbps, M12 interface |

| Wireless Network | IEEE 802.11ax/ac/a/b/g/n(2T2R), 2.400GHz~2.4835GHz, 5.150GHz~5.850GHz |

| Mobile Network | Optional full 5G support |

Other Interfaces

| USB 2.0 | 1 channel |

| Audio Output | 2 channels, 15W each |

Indicator Lights

| LAN1 Status | Green blinking |

| LAN2 Status | Green blinking |

| Status Indicator | Green blinking |

| Power Indicator | Green steady |

Special Functions

| Emergency Stop Input | 1 channel, normally closed |

| Emergency Stop Output | 1 channel, normally closed |

| Safety Edge | 1 channel, series connection, end resistance 8.2kΩ |

| Safety Input | 1 channel, normally closed |

| Function Buttons | Power, Reset, Pause, Manual/Automatic switch |

| Start Button | 1 channel, normally open |

Peripheral Interaction

| Elevator/Lift | System supports calling and floor switching for elevators/lifts, automatic map switching |

| Automatic Door/Air Shower Door | The vehicle will request to open the door when passing through and close it afterwards |

| Call Box | Tasks triggered by call boxes can be freely configured |

| Automated Equipment | Integration with equipment supporting common automation protocols for task calls and loading/unloading actions |

Map Management

| Map Building | Create maps for robot operation in the backend |

| Map Editing | Edit maps to add operation routes and points to complete business processes |

| Map Stitching | Combine multiple maps into one for larger areas |

| Batch Operations | Bulk editing of points and lines on the map |

| Automatic Sync | Automatically sync maps to other robots after editing |

Abnormal Management

| Abnormal Alerts | Pop-up or bubble alerts for anomalies |

| Log Management | Automatically filter relevant logs for analysis based on the anomaly type |

| Voice Alarms | Configure different voice alerts for different anomalies |

Human-Machine Interaction

| Real-Time Monitoring | Monitor the robot’s speed, battery level, location, status, and sensor data in real-time |

| Touch Screen Display | View and operate the robot via touch screen |

| PC Backend Display | View and operate the robot via PC |

| Modbus API | Standard Modbus API for secondary development |

| VDA5050 | Support for VDA5050 protocol for seamless integration with compliant systems |

| 5G Communication | Support for 5G to significantly reduce network instability |

| WiFi Communication | Support for WiFi with roaming switch for stable connectivity during movement |

| OTA | Support for OTA updates within the local network for program upgrades via dispatch system |

Task Management

| Task Handover | System reallocates tasks if a robot cannot complete its current task or if another robot is more suitable |

| Congestion Avoidance | Replan routes to avoid blocked paths and find the fastest available route |

| Command Control | Control specific actions and IO of the robot |

| Device Calibration | One-click calibration for key devices (laser, camera, 3D laser) |

| Relocation | Relocate the robot via screen or backend, based on station points |

| Manual Control | Control the robot manually via the interface buttons for movement |

| Multi-Robot Dispatch | Coordinate and manage multiple robots, supporting up to 1000 robots |

| Multi-Robot Collaboration | Enable multiple robots to collaboratively complete the same task |