Battery

The Challenge

High safety standards

High precision

Complex environments

Elevated production flexibility

The Solution

Integration with MBB soldering machine for loading/unloading: MES system initiates material offline/online tasks → AMS system sends tasks to Robot Control System (RCS) → Robots automatically dock with MBB soldering machine at task points to complete loading/unloading tasks before departing. Integration with inline soldering machine for loading/unloading: MES system initiates material offline/online tasks → AMS system sends tasks to Robot Control System (RCS) → Robots automatically dock with inline soldering machine at task points to complete loading/unloading tasks before departing.

The System

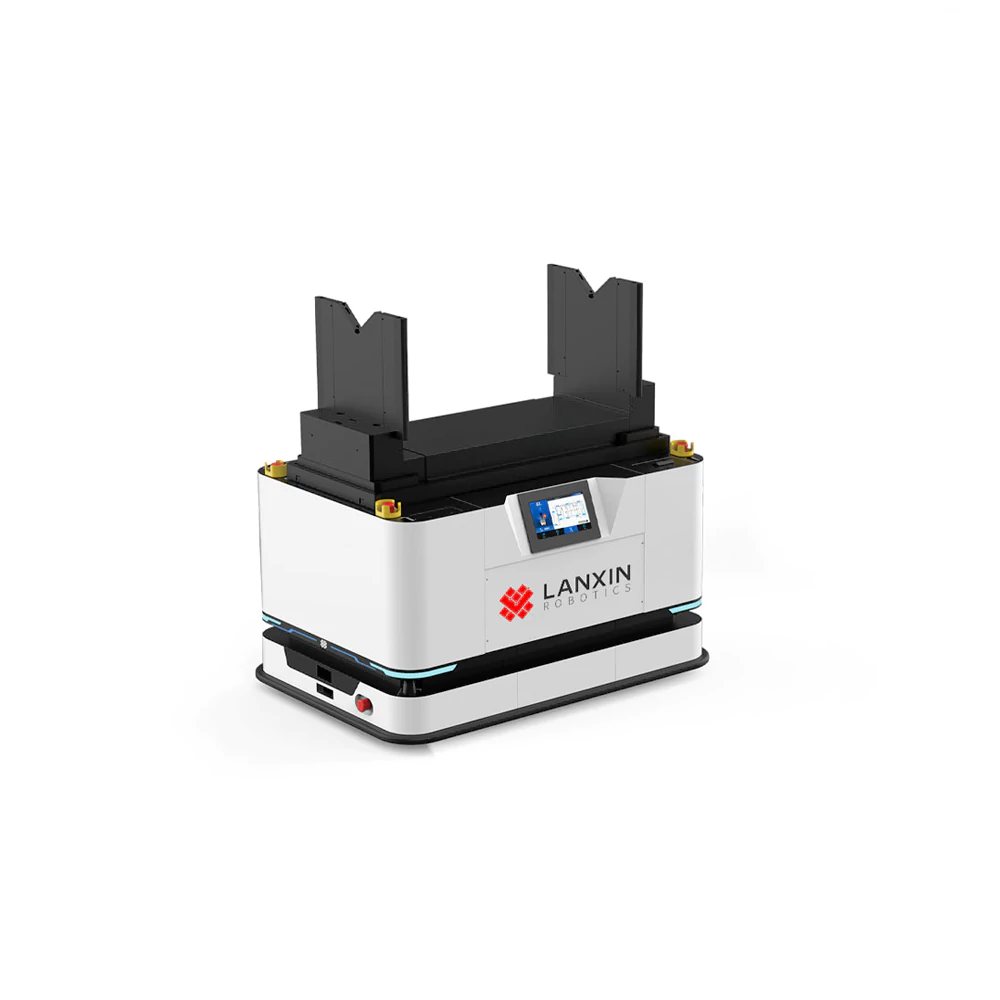

VMR-FR31000L

VMR-FL21501P

LXSR-CM51500Z

LXSR-PE41200Z

Why It Matters

Ultra-high-precision docking.

Reliable enough to boost efficiency.

LX-MRDVS® tech ensures stable positioning, navigation, and obstacle avoidance, even with glass interference.

RCS integrates with production management for scheduling, seamless tasks, connectivity, and real-time status.

At Desay

From manual carts to intelligent logistics.

Robots now move materials.

Systems stay connected.

Production stays in flow.

Automating Material Handling in Power Battery Facilities

The transportation of finished products used to rely on manual labor using hand-pulled carts. Manual handling tasks were both tedious and burdensome for workers with low efficiency. Therefore, the company aims to use robots to undertake transportation tasks to improve internal logistics efficiency.

Spot High Precision and High Safety Achived by AMR

The company specializes in lithium-ion batteries, materials, and production equipment. Its factory covers 600 ac with 50 ac of buildings, and produces 1 billion ampere-hours of batteries annually. They plan to deploy a robot logistics solution to create a more intelligent and digitized new factory.